Mining Cart Wheel

Mining wheels and kiln car wheels are mainly single wheels. The wheels mainly used for various bucket type ore truck, shuttle type ore car, mining flat plate car, side unloading type ore truck, etc. The finished products are mainly wheel sets and wheel sets form. The main material of mine wheel is cast steel, its mechanical properties is σb≥650N/mm2, σs≥300N/mm2. The wheel shafts and end covers use 45# steel (equal to 1045 steel). Kiln car wheels mainly used in the production of bricks, ceramics and other tunnel kiln cars and ferries. The wheel of kiln car has two kinds of forming methods: casting and forging. The casting wheel is made of casting carbon steel, which has excellent performance and is suitable for high temperature roasting kiln car. The forging kiln wheel has high manufactured efficiency, high tensile strength and high fatigue strength, which has a strong supporting for the kiln car in the high temperature roasted kiln.

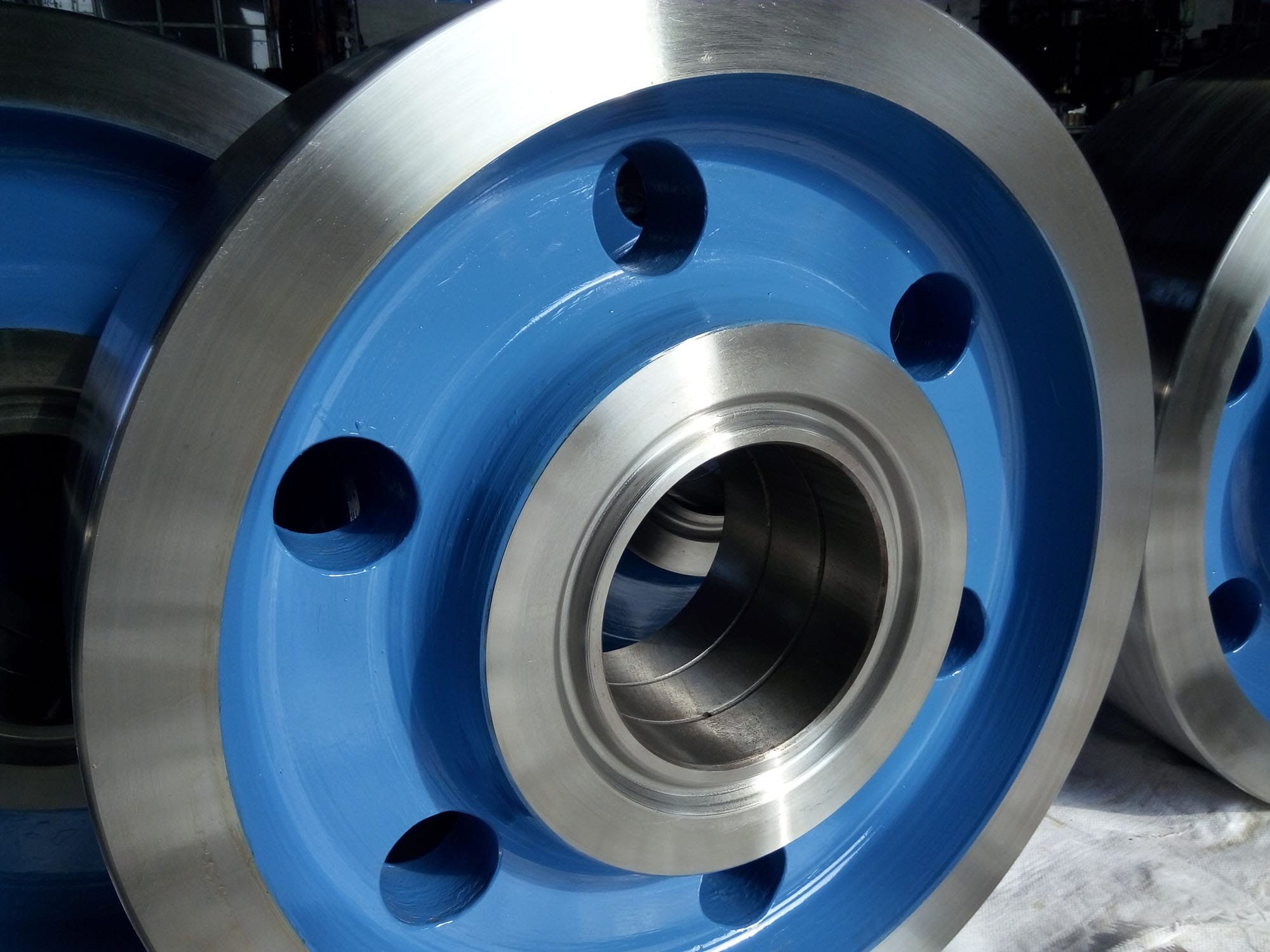

The mining car wheel manufactured by our company, uses the precision lathe processing, the wheel tread surface adopt quenching treatment, the surface hardness is greater than HB 300, the wheel can not only satisfy strength request, but also has well wear-resisting performance. The integral mechanical properties of kiln wheels greatly improved by using integral heat treatment, which well applied in the environment of high temperature tunnel kiln. Our products are of excellent quality, exported to America, South Africa, Brazil, Greece, Portugal and other countries.

Application Mining & Kiln Cart

Dry Cart

Kiln Cart

Shuttle Cart

Characteristics and Model of Mining Cart Wheel Sets

Characteristics of Mining Cart Wheel Sets:

The inner side of the mine wheel has a flange, and there is a gap between the flange and the rail. The tread of wheel contacted with rail is conical shape in order to keep the wheel pairs in alignment along the track, which can not only reduce the mechanical wear, but also reduce the running resistance.

Mine wheels are divided into cast iron mine wheel and cast steel mine wheel

Wheel base: a mining car has two sets of mining wheels, the distance between the front wheel set and the behind wheel set, in which the 1.5 ton mine cars are in the same wheel base. But for 3 ton miner because of its bottom handling, so the distance between the front and behind wheel sets is longer than the gauge.

| Model | Volume (m3) | Load | Max weigh of load | Gauge | Wheelbase | Tread | Traction height | Outer width of axle | The Traction center distance |

Buffer type | Allowable traction (KN) |

Dead weight (≤KG) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MGC1.1-6A | 1.1 | 1 | 1.8 | 600 | 550 | 300 | 320 | 808 | 1830 | single-row spring | 58.8 | 610 |

| MGC1.1-6B | 1.1 | 1 | 1.8 | 600 | 550 | 300 | 320 | 808 | 1790 | double-row spring | 58.8 | 610 |

| MGC1.7-6A | 1.7 | 1.5 | 2.7 | 600 | 750 | 300 | 320 | 828 | 2230 | single-row spring | 58.8 | 740 |

| MGC1.7-6B | 1.7 | 1.5 | 2.7 | 600 | 750 | 300 | 320 | 828 | 2190 | double-row spring | 58.8 | 760 |

| MGC1.7-9 | 1.7 | 1.5 | 2.7 | 900 | 750 | 350 | 320 | 1150 | 2200 | double-row spring | 58.8 | 980 |

| MGC3.3-9 | 3.3 | 3 | 5.3 | 900 | 1100 | 350 | 320 | 1150 | 3250 | double-row spring | 58.8 | 1320 |

Application Field

Key words: mining cart wheels, kiln car wheels

Send Us a Message.

Complete the form below, Or email to sales@dgcranewheel.com. Someone from our sales team will get back to you within 24 hours!